We at Meera specialized in yarn twisting technologies developing one by one different machine used for various application pioneered in offering carpet yarn manufacturing machines today. In continuation to this process, the market demands lead us to develop continous yarn bulking and heat setting machine.

WE ARE OFFERING MACHINE WITH THE FOLLOWING TECHNICAL SPECIFICATIONS :-

| Yarn Type | Polyester, Nylon, Polypropylene, Acrylic, Wool etc |

| No of Ends | Up to 60 |

| No of Setting Channel | 4 |

| Yarn Speed | Up to 400 MPM |

| Production | Up to 6 tons per day |

| Machine Type | Automatic |

TECHNICAL SPECIFICATIONS :-

| Yarn Type : | Polyester, Nylon, Polypropylene, Acrylic, Wool etc. |

| No. of Ends: | Up to 60 |

| No. of Setting Channel: | 4 |

| Yarn Speed : | Up to 400 MPM |

| Production | Up to 6 tons per day |

| Heat Setting Process: | Overheated steam process up to 190 degree |

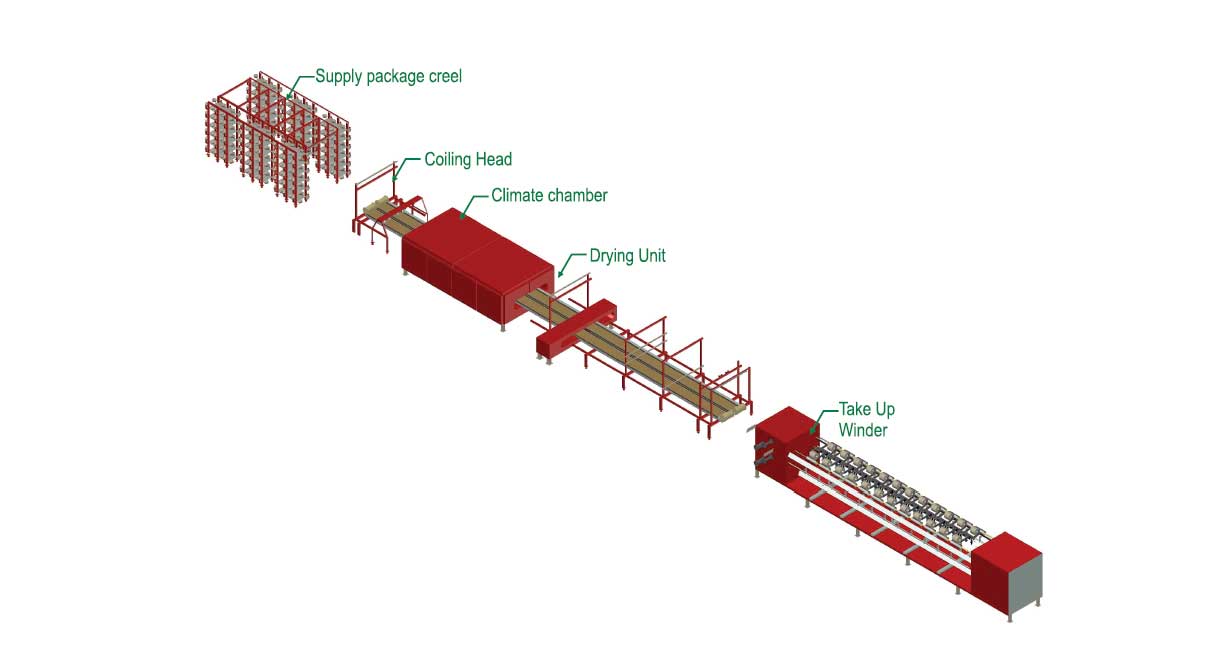

| Supply Creel: | Facilitated with two package stand for transfer tail and yarn break detector. |

| Coiling Head: | Coiling head to lay yarn on conveyor lead to climate chamber. |

| Conveyer Belts: | Teflon coated yarn transport belts driven by PLC controlled geared motor to very Dwell time ranging from 40 secs to 10 mins. |

| Climate Chamber: | Heat setting chamber having temperature as well as humidity control to set requisite yarn bulk and heat setting of yarn. |

| Yarn Dryer: | Yarn cooling area after heat setting of yarn to drop the yarn at room temperature. |

| Yarn Splitting: | Yarn bundle of 16 ends get separated after cooling for final winding of yarn in individual package ready for use. |

| Final Winder: | Take up winder to builds final package of yarn duly bulked and heat sated ready for tufting carpet up to capacity of 4 kgs. |

| Electricals & Electronics: | Complete controlling of heat set process is done by PLC controlled yarn sensing, yarn speed, dwell time, chamber temperature, yarn speed at take up in synchronizing ways to achieve desired uniform yarn bulking and heat setting. |

| Over All Dimension: | Space requirements of the machine is of 14 feed width by 95 feet long from yarn feeding to final winder. |

COUNTINUOUS BULKING & HEAT SETTING MACHINE FOR CARPET YARN :-